The drinking water sector faces significant challenges in ensuring the availability and reliability of water for the future. To meet these demands, Rodelta has developed an efficient, sustainable, and future-proof solution. The newly designed prefabricated concrete pump stations offer an innovative approach that combines standardization, quality, planning efficiency, and environmental benefits in a single, robust design.

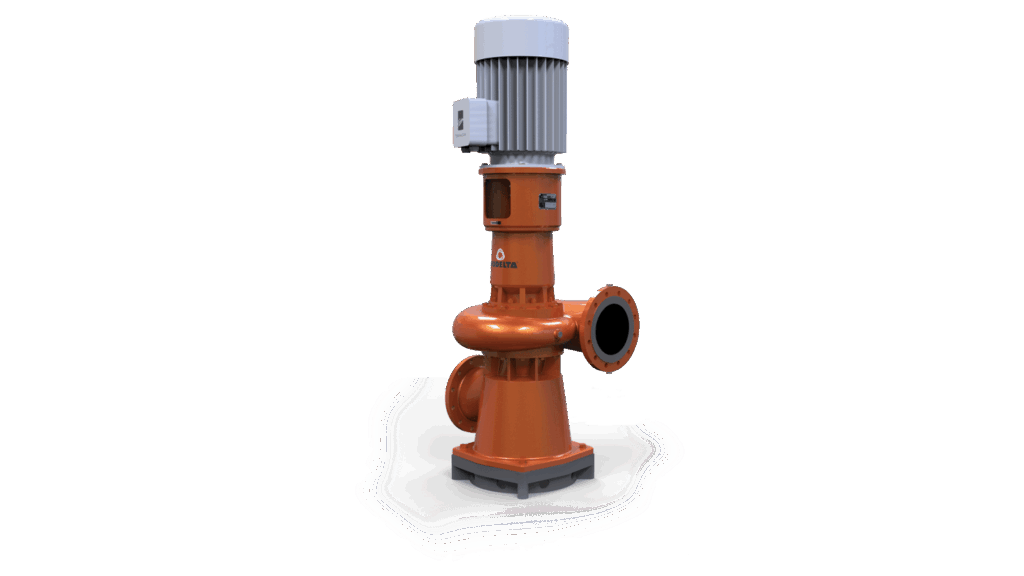

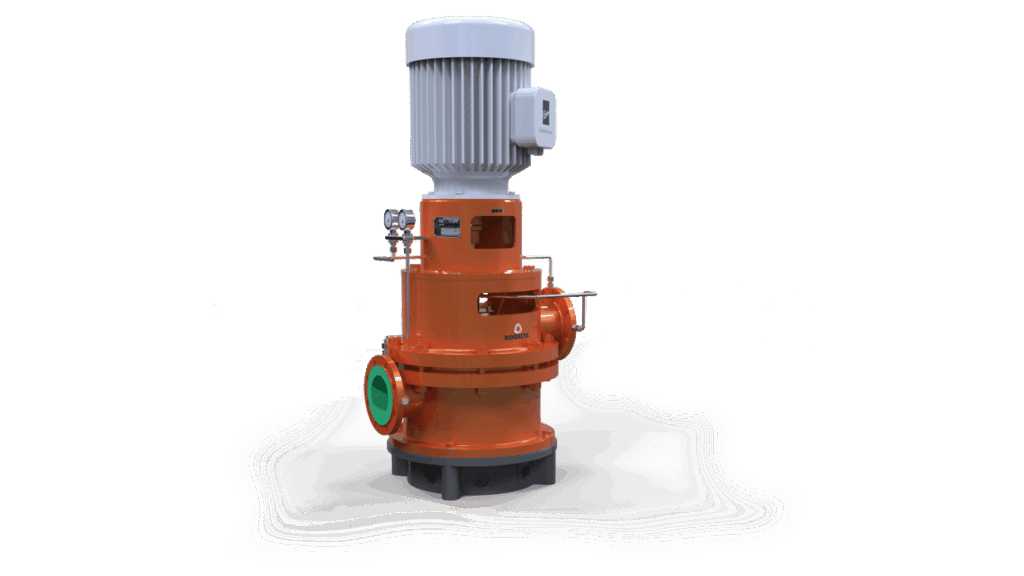

In this concept, the pump unit is fully integrated into a prefabricated concrete underground structure. The result is a compact, reliable, and low-maintenance system that is easily reproducible and can be quickly deployed across different locations. The prefabricated structure serves as a waterproof, durable, and robust housing, safely and efficiently accommodating all pumping equipment.

Production under controlled factory conditions ensures consistent, high-quality construction, independent of weather conditions or local site challenges. This leads to shorter project timelines, reduced risk of errors, and increased operational reliability.

Key Benefits:

Rapid installation – from production to operational system in just a few days;

Fully waterproof and durable design, ideal for groundwater-sensitive sites;

Standardized design, easily scalable and suitable for stock production;

Flexible configurations for different pump capacities, pipe entries, and access solutions;

Use of geopolymer concrete – with up to 80% lower CO₂ emissions compared to traditional concrete;

Faster permitting processes due to uniform design and predictable quality;

Reduced workload for engineering teams thanks to modular standardization.

This innovation brings together technical reliability, construction efficiency, and sustainability in a single integrated solution.

Rodelta’s prefabricated pump stations thus set a future-proof standard for pressure boosting and water transport, designed for a circular and environmentally friendly water sector.